Tungsten carbide knives for Lithium battery Industry - Manufacturers, Suppliers, Factory from China

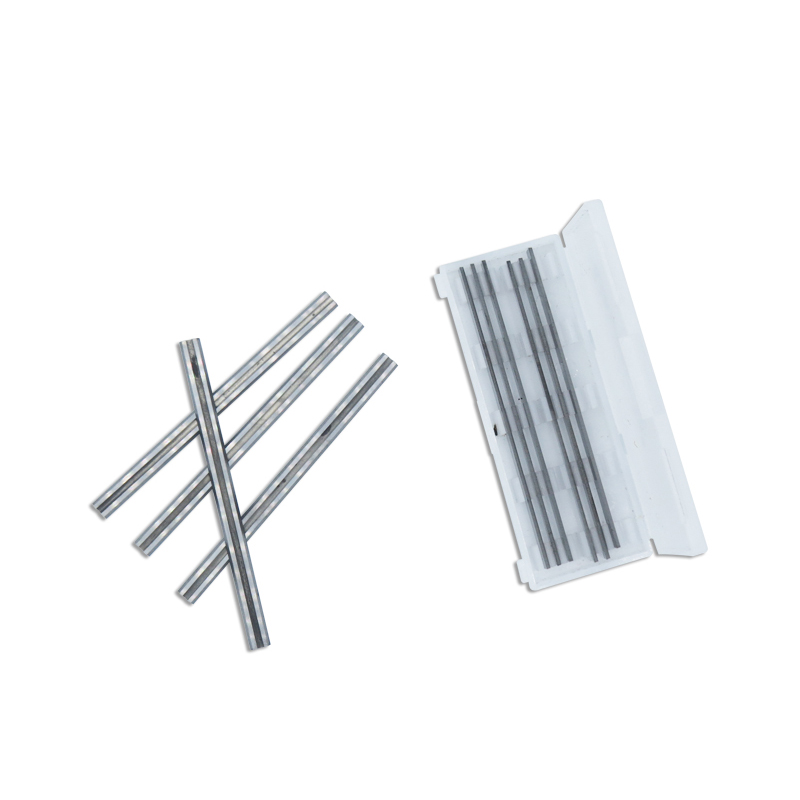

Let's see the manufacturing process of carbide. First, mix tungsten carbide with cobalt to make powder which can be classified as raw materials. The granulated mixture is poured into a die cavity and pressed. It gives a moderate strength like that of chalk. Next, the pressed compacts are placed in a sintering furnace and heated at a temperature of about 1400°C,resulting in cemented carbide. After sintering, content volume shrinks considerably. Finally, the product is pressed into a specified shape by means of a mould, and the carbide product is obtained.

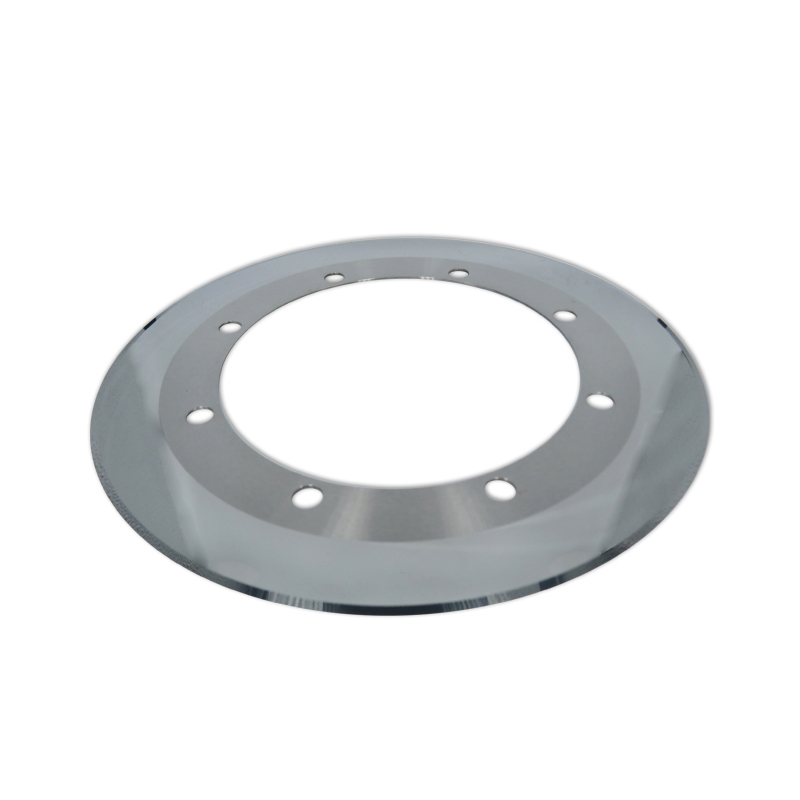

Related Products