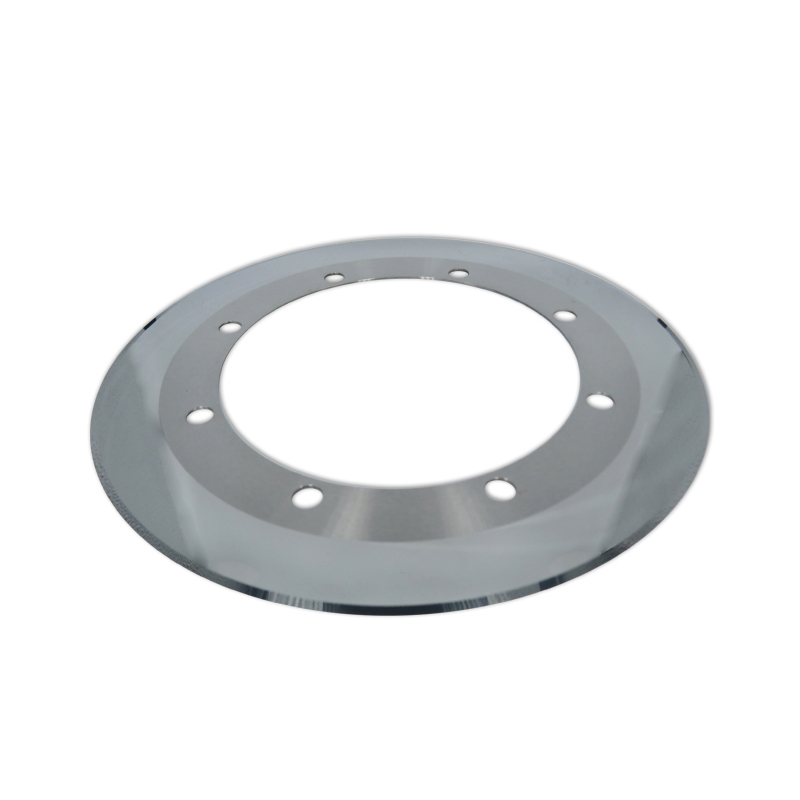

Best quality Tungsten Knife - Marquip Carbide Circular Corrugated Slitting Knives – Xinhua

Best quality Tungsten Knife - Marquip Carbide Circular Corrugated Slitting Knives – Xinhua Detail:

Application areas

The cemented carbide corrugated paper circular knives made by tungsten carbide and cobalt powder metallurgy have high hardness and wear resistance, and at the same time have good heat resistance and corrosion resistance, so that the knives are widely used in the cutting of corrugated cardboard.

By adjusting the ratio of tungsten carbide and cobalt and the particle size of tungsten carbide powder, we obtain cemented carbides with different properties to meet the needs of different customers.

Our advantage

Our company has more than 20 years of production history of tungsten carbide slitting knives, specializing in the production of tungsten carbide corrugated paper round knives and various carbide slitting knives.

More than half of the products are exported to Europe, the United States and other developed countries and regions. Product performance fully meets the strict requirements of various high-speed slitting equipments. Product quality is in a leading position in the domestic and foreign industrial tool market segments.

Our company’s goal is to become the most professional, best quality, and largest supplier of tungsten steel slitting knives.

Process Flow

Recommended Materials

| Grade | Grain Size | Density | Hardness | TRS(N/mm²) | Suitable for Cutting |

| g/cm³ | HRA | ||||

| ZT20U | Sub-fine | 14.35-14.5 | 91.4-91.8 | 3200 | Corrugated board,Chemical fiber,Plastics,Leather |

| ZT26U | Sub-fine | 14-14.1 | 90.4-90.8 | 3500 | Corrugated board,Battery pole pieces |

| ZT30U | Sub-fine | 13.85-14 | 89.7-90.2 | 3200 | Paperboard |

Common Specifications

| Items No | OD (mm) | ID (mm) | T (mm) | Holes(mm) | Available for Machine |

| 1 | 230 | 110 | 1.1 | φ9*6holes | FOSBER |

| 2 | 230 | 135 | 1.1 | 4 key slots | FOSBER |

| 3 | 220 | 115 | 1 | φ9*3holes | AGNATI |

| 4 | 240 | 32 | 1.2 | φ8.5*2holes | BHS |

| 5 | 240 | 115 | 1 | φ9*3holes | AGNATI |

| 6 | 250 | 150 | 0.8 | PETERS | |

| 7 | 257 | 135 | 1.1 | FOSBER | |

| 8 | 260 | 112 | 1.5 | φ11*6holes | ORANDA |

| 9 | 260 | 140 | 1.5 | ISOWA | |

| 10 | 260 | 168.3 | 1.2 | φ10.5*8holes | MARQUIP |

| 11 | 270 | 168.3 | 1.5 | φ10.5*8holes | HSEIH |

| 12 | 270 | 140 | 1.3 | φ11*6holes | VATANMAKEINA |

| 13 | 270 | 170 | 1.3 | φ10.5*8holes | |

| 14 | 280 | 160 | 1 | φ7.5*6holes | MITSUBISHI |

| 15 | 280 | 202 | 1.4 | φ8*6holes | MITSUBISHI |

| 16 | 291 | 203 | 1.1 | φ8.5*6holes | FOSBER |

| 17 | 300 | 112 | 1.2 | φ11*6holes | TCY |

Knives for corrugated board cutting For Chinese Machines

| Items No | OD (mm) | ID (mm) | T (mm) | Holes |

| 1 | 200 | 122 | 1.2 | |

| 2 | 210 | 110 | 1.5 | |

| 3 | 210 | 122 | 1.3 | |

| 4 | 230 | 110 | 1.3 | |

| 5 | 230 | 130 | 1.5 | |

| 6 | 250 | 105 | 1.5 | φ11mm*6holes |

| 7 | 250 | 140 | 1.5 | |

| 8 | 260 | 112 | 1.5 | φ11mm*6holes |

| 9 | 260 | 114 | 1.6 | φ11mm*8holes |

| 10 | 260 | 140 | 1.5 | |

| 11 | 260 | 158 | 1.5 | φ11mm*8holes |

| 12 | 260 | 112 | 1.4 | φ11mm*6holes |

| 13 | 260 | 158 | 1.5 | φ9.2mm*3holes |

| 14 | 260 | 168.3 | 1.6 | φ10.5mm*8holes |

| 15 | 260 | 170 | 1.5 | φ9mm*8holes |

| 16 | 265 | 112 | 1.4 | φ11mm*6holes |

| 17 | 265 | 170 | 1.5 | φ10.5mm*8holes |

| 18 | 270 | 168 | 1.5 | φ10.5mm*8holes |

| 19 | 270 | 168.3 | 1.5 | φ10.5mm*8holes |

| 20 | 270 | 170 | 1.6 | φ10.5mm*8holes |

| 21 | 280 | 168 | 1.6 | φ12mm*8holes |

| 22 | 290 | 112 | 1.5 | φ12mm*6holes |

| 23 | 290 | 168 | 1.5/1.6 | φ12mm*6holes |

| 24 | 300 | 112 | 1.5 | φ11mm*6holes |

FAQ for technical problems

Analysis of the common problems of corrugated board slitting knives

(Not: all the problems we discussed for the qualified knives )

Q1 Why The Short working life time of currugated board slitting knives?

A :Is the grain size of the grinding wheel proper?

Too coarse grain size of grinding wheel make a short working life time of knives

Q2 Why the edges of corrugated boards cut by knives with burr and dent?

A:Please check the cutting edge of your knives ,is the cutting edge keen enough? Or if the corrrugated board is too wet ?

Q3 Knives broken

A: Improper assembly (e.g deformed flange plate; improper screwing) will cause the quick break of blades , any improper touch of the blades is strictly prohibited during the working ,

Unstable swing grinding wheels break the knives,please check the bearing of grinding wheels .

Improper touch or strike with other hard things.

Accident collision of knives

Q4 Chips on the cutting edge after the grinding.

A: Unstable swing grinding wheels may cause this problem , even break the knives , The strike of hard things may cause the chips on the cutting edge also .

Q5 Why the edge of corrugated board is not straight ?

A:Unmatched strength of knives for the corrugated board with high density .

FAQ about pre-sales and after-sales

Q:Can I get free testing samples?

A:Yes, if you have a clear demand, we can provide free samples for testing.

Q:How about the leading time ?

A:We have regular specifications in stock, and can be shipped within three days after confirming the contract.

Q:Can you also supply steel handles?

Yes, we have handle suppliers that have cooperated for many years, and can provide you stell scraper handles with high-quality, low-price .

Q:Can your factory provide OEM production?

A:Yes, if your purchase quantity meets the requirements, we can design the packaging for you according to your requirements

Q:Do you guarantee the quality?

Yes, we have quality-guaranteed tracking services for the products that have been sold. If you have any questions, please feel free to contact our sales staff. You will get satisfactory after-sales service within 24 hours.

Product detail pictures:

Related Product Guide:

Our growth depends on the superior equipment ,exceptional talents and continuously strengthened technology forces for Best quality Tungsten Knife - Marquip Carbide Circular Corrugated Slitting Knives – Xinhua , The product will supply to all over the world, such as: Brazil, Johannesburg, Poland, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.