Manufacturer of Carbide Burr Bits For Metal - Carbide Rotary Burr SA Shape -Cylinder Shape – Xinhua

Manufacturer of Carbide Burr Bits For Metal - Carbide Rotary Burr SA Shape -Cylinder Shape – Xinhua Detail:

Features

*Capable of machining variours metal (including defferent quenching steel) and non-metal materials such as marble, jade and bone. With hardness up to HRC70,.

*To replace small shank grinding wheel in most instances, no dust contamination produced.,

*Good machining quality and high smoothness suitable for machining various mould cavity with high accuracy ;

*Long service life ,10 times the high speed steel tools and 200 times the small grinding wheel in durability.

*Easy to handle and operate. Safe and reliable, able to reduce labour intensity and improve working condition;

*high economic benefit, may have 10% reduction in comprehesive process cost .

Usually ,the rotational speed of electric or pneumatic tools should be 6000-50000 per minute.

For safe use ,carbide rotary burrs must be correctly clamped during operation ,to avoid reciprocally feeding , reverse mill is more favourable. To protect your eyes with protective spectacles and prevent chip from splash at the same time .

Application

1:Trimming flash edges ,burrs and welding lines of casting,forging and welding parts;

2: Finish machining various kinds of metal molds ;

3:Finish cutting of vane wheel runner;

4:Chamfering ,rounding and channelling of various kinds of machinery parts;

5:Finish machining the surface of inner bore of machinery parts;

6:Artistic engraving of all kinds of metal or non-metal parts;

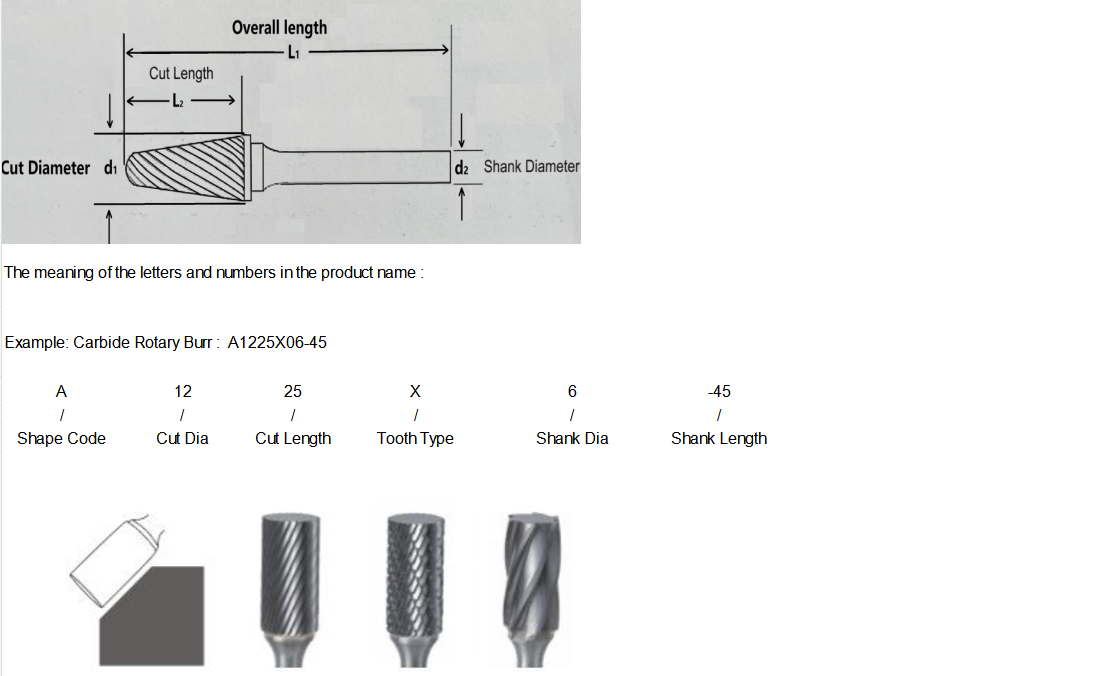

Types of Cutting Edges

| Types of Cutting Edge | Images | Application |

| Single Cut M |  |

The standard single cutting head ,serrated shape is fine,and the surface finish is good,it is suitable for processing hardened steel with hardness HRC40-60 degrees,heat resistant alloy,nikel base alloy ,Cobalt based alloy,stainless steel,etc |

| Double Cut X |  |

This double cutting shape has short chip and high surface finish, it is suitable for processing cast iron,cast steel ,steel with hardness less than HRC60,Nikel based alloy ,cobalt based alloy,austenitic stainless steel,titanium alloy,etc. |

| Aluminium Cut W |  |

The Aluminium cutting shape has a large chip pocket, a very sharp cutting edge and fast chip removal , it is suitable for processing aluminium ,aluminium alloy ,light metal ,non-ferrous metal,plastic ,hard rubber ,wood and so on |

Main Specifications

| Shape and Type | Order No. | Size | Tooth Type | ||||

| Head Dia (mm) d1 | Head Length (mm) L2 | Shank Dia (mm) d2 | Total Length (mm ) L1 | ||||

| Cylinder Shape Type A | A0313X03-25 | 3 | 13 | 3 | 38 | X | |

| A0413X03-38 | 4 | 13 | 3 | 51 | X | ||

| A0613X03-38 | 6 | 13 | 3 | 51 | X | ||

| A0616X06-45 | 6 | 16 | 6 | 61 | X | ||

| A0820X06-45 | 8 | 20 | 6 | 65 | X | ||

| A1020X06-45 | 10 | 20 | 6 | 65 | X | ||

| A1225X06-45 | 12 | 25 | 6 | 70 | X | ||

| A1425X06-45 | 14 | 25 | 6 | 70 | X | ||

| A1625X06-45 | 16 | 25 | 6 | 70 | X | ||

FAQs

Q:Can I get free testing samples?

A:Yes, if you have a clear demand, we will provide free samples for testing.

Q:How about the leading time ?

A:We have regular specifications in stock, stock goods 3 days. For sustomized products , 25 days.

Q:Can your factory provide OEM production?

A:Yes, if your purchase quantity meets the requirements, we can design the packaging for you according to your requirements

Q:Can you sell them the carbide burrs in the form of the suit?

A:Yes ,we have folding plastic boxes , 5pcs/8pcs/10 pcs packaging form is available

Q:Do you guarantee the quality?

Yes, we have quality-guaranteed tracking services for the products that have been sold. If you have any questions, please feel free to contact with us. You will get satisfactory after-sales service within 24 hours.

Product detail pictures:

Related Product Guide:

Our firm has been concentrating on brand strategy. Customers' satisfaction is our best advertising. We also offer OEM provider for Manufacturer of Carbide Burr Bits For Metal - Carbide Rotary Burr SA Shape -Cylinder Shape – Xinhua , The product will supply to all over the world, such as: Paris, European, Romania, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.