OEM Customized High Quality Carbide Burrs Rotary File for Wholesale 6mm Tungsten Carbide Cutting

We generally stick to the theory “Quality Very first, Prestige Supreme”. We’ve been fully committed to furnishing our shoppers with competitively priced high quality solutions, prompt delivery and expert services for OEM Customized High Quality Carbide Burrs Rotary File for Wholesale 6mm Tungsten Carbide Cutting, Our goal should be to create Win-win situation with our prospects. We imagine we will be your finest choice. “Reputation 1st, Customers Foremost. “Waiting for your inquiry.

We generally stick to the theory “Quality Very first, Prestige Supreme”. We’ve been fully committed to furnishing our shoppers with competitively priced high quality solutions, prompt delivery and expert services for China Carbide Burrs and Tungsten, With more and more Chinese products around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to offer you both better products and service, because we are more and more powerful, professional and experience in domestic and international.

Features

*Capable of machining variours metal (including defferent quenching steel) and non-metal materials such as marble, jade and bone. With hardness up to HRC70,.

*To replace small shank grinding wheel in most instances, no dust contamination produced.,

*Good machining quality and high smoothness suitable for machining various mould cavity with high accuracy ;

*Long service life ,10 times the high speed steel tools and 200 times the small grinding wheel in durability.

*Easy to handle and operate. Safe and reliable, able to reduce labour intensity and improve working condition;

*high economic benefit, may have 10% reduction in comprehesive process cost .

Usually ,the rotational speed of electric or pneumatic tools should be 6000-50000 per minute.

For safe use ,carbide rotary burrs must be correctly clamped during operation ,to avoid reciprocally feeding , reverse mill is more favourable. To protect your eyes with protective spectacles and prevent chip from splash at the same time .

Application

1: Trimming flash edges ,burrs and welding lines of casting,forging and welding parts;

2: Finish machining various kinds of metal molds ;

3: Finish cutting of vane wheel runner;

4: Chamfering ,rounding and channelling of various kinds of machinery parts;

5: Finish machining the surface of inner bore of machinery parts;

6: Artistic engraving of all kinds of metal or non-metal parts;

Types of Cutting Edges

| Types of Cutting Edge | Images | Application |

| Single Cut M |  |

The standard single cutting head ,serrated shape is fine,and the surface finish is good,it is suitable for processing hardened steel with hardness HRC40-60 degrees,heat resistant alloy,nikel base alloy ,Cobalt based alloy,stainless steel,etc |

| Double Cut X |  |

This double cutting shape has short chip and high surface finish, it is suitable for processing cast iron,cast steel ,steel with hardness less than HRC60,Nikel based alloy ,cobalt based alloy,austenitic stainless steel,titanium alloy,etc. |

| Aluminium Cut W |  |

The Aluminium cutting shape has a large chip pocket, a very sharp cutting edge and fast chip removal , it is suitable for processing aluminium ,aluminium alloy ,light metal ,non-ferrous metal,plastic ,hard rubber ,wood and so on |

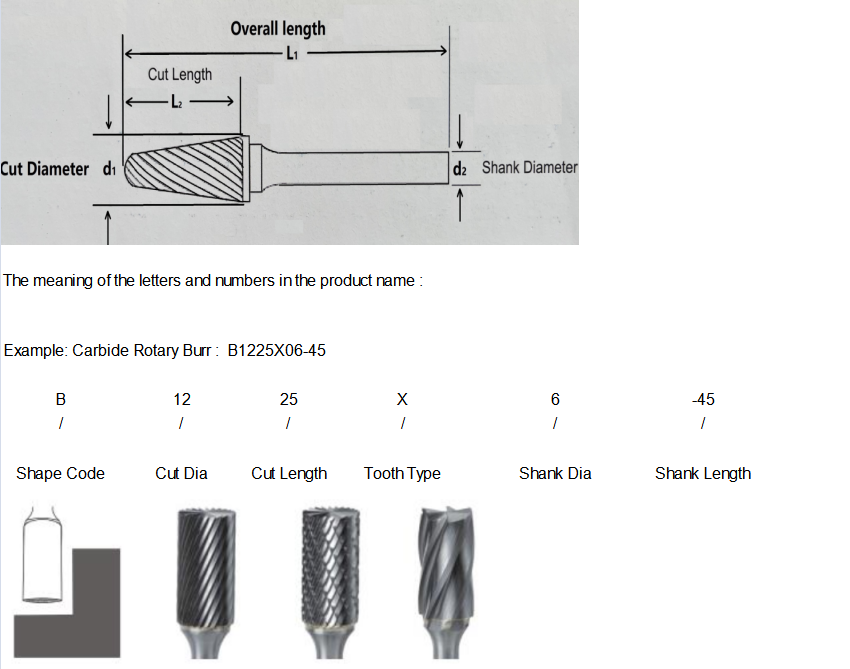

Main Specifications

| Shape and Type | Order No. | Size | Tooth Type | ||||

| Head Dia (mm) d1 | Head Length (mm) L2 | Shank Dia (mm) d2 | Total Length (mm ) L1 | ||||

| Cylinder Shape with End Cut Type B | B0313X03-25 | 3 | 13 | 3 | 38 | X | |

| B0413X03-38 | 4 | 13 | 3 | 51 | X | ||

| B0613X03-38 | 6 | 13 | 3 | 51 | X | ||

| B0616X06-45 | 6 | 16 | 6 | 61 | X | ||

| B0820X06-45 | 8 | 20 | 6 | 65 | X | ||

| B1020X06-45 | 10 | 20 | 6 | 65 | X | ||

| B1225X06-45 | 12 | 25 | 6 | 70 | X | ||

| B1425X06-45 | 14 | 25 | 6 | 70 | X | ||

| B1625X06-45 | 16 | 25 | 6 | 70 | X | ||

FAQs

Q:Can I get free testing samples?

A:Yes, if you have a clear demand, we will provide free samples for testing.

Q: What is your welding method ?

A: Silver welding , This is the mainstream welding method for high-quality products .

Q:How about the leading time ?

A:We have regular specifications in stock, stock goods 3 days. For sustomized products , 25 days.

Q:Can your factory provide OEM production?

A:Yes, if your purchase quantity meets the requirements, we can design the packaging for you according to your requirements

Q:Can you sell them the carbide burrs in the form of the suit?

A:Yes ,we have folding plastic boxes , 5pcs/8pcs/10 pcs packaging form is available

Q:Do you guarantee the quality?

Yes, we have quality-guaranteed tracking services for the products that have been sold. If you have any questions, please feel free to contact with us. You will get satisfactory after-sales service within 24 hours.

Introducing the Carbide Burr Tool – the perfect tool for all your grinding and shaping needs. This innovative tool is designed to make your work easier, quicker and more efficient.

The Carbide Burr Tool is made of a high-quality carbide material. This material is known for its strength and durability, making it perfect for tough grinding jobs. The tool features a cylindrical shape with a variety of head shapes to suit your needs.

Whether you are working on wood, metal or other materials, the Carbide Burr Tool will help you achieve perfect shapes and smooth finishes. Its sharp edges cut through the material with ease, ensuring that your work is flawless every time.

The tool comes in a wide range of sizes, depending on your specific needs. The smallest size is perfect for fine detail work, while the larger sizes are ideal for heavy-duty grinding.

With its easy-to-use design, the Carbide Burr Tool is perfect for both beginners and professionals alike. Its comfortable grip allows for long periods of use without causing discomfort. Its compact size also makes it easy to store and transport.

The versatility of the Carbide Burr Tool is unmatched. It can be used for a variety of functions, including carving, grinding, drilling, and polishing. It is perfect for use in automotive repair, metalworking, woodworking, and even jewelry making.

One of the biggest advantages of the Carbide Burr Tool is its longevity. Unlike other grinding tools, the Carbide Burr Tool does not require frequent sharpening, making it a cost-effective choice for those who use it frequently.

Overall, the Carbide Burr Tool is a game-changer for anyone who wants to achieve perfect grinding and shaping results. Its durable construction, comfortable grip, and versatile design make it a must-have for any workshop. Whether you are a beginner or a professional, the Carbide Burr Tool will help you achieve the perfect results every time. So why wait? Get your Carbide Burr Tool today and experience the difference for yourself!